Overview

Earthing systems play a crucial role in ensuring electrical safety, and their significance is underlined by the Indian Electricity Rules, 1956. These rules provide a framework to regulate electrical installations and ensure the protection of life and property. In this blog, we will delve into the essentials of earth pits, earthing systems, and related concepts as outlined in the Indian Electricity Rules, 1956. We’ll also explore how these systems contribute to safety and compliance.

IN THIS ARTICLE

Overview

Earthing System

IE Rules

Benefits

Conclusion

What is Earthing?

Earthing refers to the process of transferring the immediate discharge of electrical energy directly to the earth using a low-resistance wire. It ensures that electrical faults do not lead to hazardous conditions. The earthing system includes:

Earth electrodes or earth pits

Conductors connecting the installation to the earth

Protective devices that ensure the safety of people and equipment

IE Rules

Importance of Earthing Systems in Electrical Safety

Earthing systems play a vital role in safeguarding life and property. They prevent electric shocks, reduce the risk of fire, and ensure the effective operation of protective devices. The Indian Electricity Rules, 1956, outline detailed provisions to achieve these objectives.

Earthing refers to the process of transferring the immediate discharge of electrical energy directly to the earth using a low-resistance wire. It ensures that electrical faults do not lead to hazardous conditions. The earthing system includes:

Earth electrodes or earth pits

Conductors connecting the installation to the earth

Protective devices that ensure the safety of people and equipment

Indian Electricity Rules, 1956 Related to Earthing System

1. General Earthing Requirements

Conducting Objects: Every conducting object, other than current-carrying parts, must be effectively earthed.

Earthing Lead Dimensions: Minimum sizes for earthing leads are specified as 50 sq. mm for copper and 75 sq. mm for aluminum.

Continuity: Earth continuity within premises must be maintained and tested periodically.

2. Specific Rules for Earth Pits

Earth pits must have a resistance of not more than 5 ohms and should be maintained consistently.

Two separate and distinct earth electrodes are required for installations such as public lighting systems.

3. Neutral Conductor Earthing

In three-phase, four-wire systems, the neutral conductor must be earthed using two separate and distinct connections with a minimum of two earthing electrodes.

This reduces the overall earthing resistance to an acceptable low value.

4. High Voltage and Medium Voltage Systems

Rule 53: High voltage installations require two earth electrodes, separated by at least 6 meters.

Rule 52(2): Medium voltage installations must have two independent earth electrodes.

5. Earthing of Equipment and Metal Parts

Stationary and Portable Equipment: Frames of motors, transformers, generators, and metallic parts of controlling apparatus must have two distinct earthing connections.

Metal Castings and Covers: All metal coverings protecting electrical lines or equipment must be earthed unless classified as Class II appliances.

Types of Earthing Systems

1. Plate Earthing

Uses a copper or galvanized iron plate buried at a suitable depth.

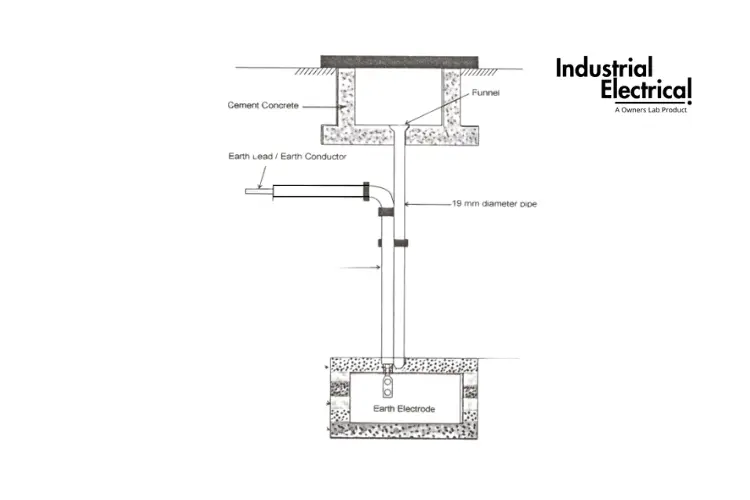

2. Pipe Earthing

Involves burying a galvanized iron pipe vertically, suitable for locations with high soil resistivity.

3. Strip Earthing

Employs flat strips of copper or galvanized iron laid in trenches.

Read our articles:

Energy Audits: How to Identify and Reduce Power Consumption in Industrial Plants

In today’s competitive industrial landscape, reducing energy consumption is not just about cutting costs; it’s about ensuring sustainability and operational efficiency. Industrial plants are some of the largest consumers of energy, which means they have a substantial impact on both the environment and their own bottom line.

Maintaining and Testing Earthing Systems

Periodic testing of earthing resistance is essential to ensure compliance with the 5-ohm resistance requirement.

Interconnection of earth electrodes can further reduce resistance.

No impedance, circuit breaker, or cut-out should interrupt the earthing system.

Benefits of Effective Earthing

- Human Safety: Protects against electric shocks.

Equipment Protection: Prevents damage from overvoltage or lightning.

System Reliability: Enhances the performance of protective devices like circuit breakers.

Regulatory Compliance: Adherence to the Indian Electricity Rules, 1956, avoids legal penalties and ensures operational safety.

Electrical regulations and standards :

In most countries, electrical installations shall comply with more than one set of regulations, issued by National Authorities or by recognized private bodies. It is essential to take into account these local constraints before starting the design.

These regulations may be based on national standards derived from the IEC 60364: Low-voltage electrical installations.

Conclusion

Equipment Protection: Prevents damage from overvoltage or lightning.

System Reliability: Enhances the performance of protective devices like circuit breakers.

Regulatory Compliance: Adherence to the Indian Electricity Rules, 1956, avoids legal penalties and ensures operational safety.

Pingback: What is harmonics and how to reduce harmonics -