Excitation System in High Tension (HT) Motors

High Tension (HT) motors, also known as high voltage motors, are used in applications requiring significant power output, typically operating at voltages above 1,000 volts. These motors often require an excitation system to control the magnetic field in the rotor, ensuring efficient and stable operation. The excitation system plays a critical role in the performance of HT motors, especially synchronous motors, which need a controlled magnetic field for proper synchronization with the power supply frequency.

Table of Contents

What is an Excitation System?

An excitation system in HT motors is responsible for providing the necessary field current to the rotor. This system ensures the creation and maintenance of the rotor’s magnetic field, which interacts with the stator’s rotating magnetic field to produce torque. The excitation system regulates this field current to maintain optimal motor performance, stability, and efficiency.

Why Excitation Systems are Used in High Tension (HT) Motors

Excitation systems are crucial for the operation of High Tension (HT) motors, particularly synchronous motors. These systems provide the necessary field current to the rotor, ensuring the creation and maintenance of the magnetic field required for motor operation. Here are the primary reasons why excitation systems are used in HT motors:

1. Voltage Regulation

One of the key roles of an excitation system is to regulate the voltage output of the motor. The excitation system adjusts the field current to maintain a consistent voltage level, ensuring stable operation even under varying load conditions. This regulation is essential for maintaining the efficiency and reliability of power supply systems.

2. Reactive Power Control

Excitation systems help in controlling the reactive power flow in electrical systems. By adjusting the excitation current, the system can manage the motor’s reactive power generation, which is critical for maintaining the power factor. A good power factor reduces energy losses and improves the efficiency of power distribution networks.

3. System Stability

HT motors, especially in industrial and power generation applications, often experience significant load changes. An excitation system provides the necessary adjustments to the field current, helping to stabilize the motor during these fluctuations. This stability is crucial for preventing power outages and ensuring continuous, reliable operation.

4. Improved Efficiency

By optimizing the field current, excitation systems enhance the efficiency of HT motors. Proper excitation reduces energy losses, minimizes heat generation, and ensures that the motor operates at peak performance levels. This efficiency translates to lower operational costs and improved longevity of the motor.

5. Enhanced Motor Performance

The performance of synchronous motors, a common type of HT motor, heavily relies on the excitation system. Proper excitation ensures that the motor maintains synchronization with the power supply frequency, providing consistent speed and torque. This consistency is vital for applications requiring precise control, such as in industrial machinery and power generation.

6. Protection and Safety

Excitation systems are equipped with protection mechanisms to safeguard the motor against abnormal conditions like overvoltage, overcurrent, and overheating. These protective features help prevent damage to the motor, ensuring safe and reliable operation.

7. Load Sharing

In applications where multiple HT motors are used in parallel, excitation systems help in load sharing by balancing the reactive power among the motors. This load sharing ensures that no single motor is overburdened, distributing the load evenly and enhancing the overall efficiency and reliability of the system.

8. Dynamic Response

Modern excitation systems, especially static excitation systems, offer fast dynamic response to changes in load conditions. This rapid response capability is crucial for applications where quick adjustments are necessary to maintain stability and performance, such as in power plants and industrial processes.

Types of Excitation Systems in HT Motors

There are several types of excitation systems used in HT motors, particularly synchronous motors. These include:

- Static Excitation System

- Brushless Excitation System

- Rotating Exciter System

- AC Exciter System

Each of these systems has its unique components and operational characteristics.

Understanding Static Excitation Systems

Static excitation systems are pivotal in the efficient operation of synchronous machines, including both motors and generators. These systems provide the necessary field current to the rotor, ensuring optimal performance, stability, and control. This article explores the working principles of static excitation systems, their components, how they function, and the various applications where they are utilized.

What is a Static Excitation System?

A static excitation system is a modern method of providing excitation current to the rotor of a synchronous machine. Unlike traditional methods that use mechanical means or rotating exciters, static excitation systems employ solid-state electronics to supply and control the field current. This approach offers several advantages, including improved reliability, efficiency, and precision in voltage regulation.

Components of a Static Excitation System

While the specific components may vary depending on the type of excitation system, the core components generally include:

- Voltage Sensing Unit: Monitors the output voltage of the motor and provides feedback for regulation.

- Excitation Controller: Processes the feedback and adjusts the excitation current to maintain the desired voltage level.

- Rectifier Unit: Converts AC supply voltage to DC voltage, which is supplied to the rotor field winding.

- Power Electronic Devices: Includes thyristors, IGBTs, or other semiconductor devices to control the magnitude of the DC excitation current.

- Excitation Transformer: Steps down the voltage to a suitable level for the rectifier unit.

- Protection and Control Systems: Ensures safe operation by protecting against overcurrent, overvoltage, and other faults.

How Static Excitation Systems Work ?

The operation of excitation systems in HT motors involves several key steps:

Voltage Sensing and Feedback:

- The voltage sensing unit continuously monitors the motor’s output voltage. This real-time data is fed back to the excitation controller.

Excitation Control:

- The excitation controller compares the sensed voltage with a reference voltage. If there is a discrepancy, the controller calculates the necessary adjustments to the excitation current.

Rectification:

- The AC voltage from the excitation transformer is converted to DC voltage by the rectifier unit. This DC voltage is required to energize the rotor field winding.

Power Electronics Regulation:

- Power electronic devices, such as thyristors or IGBTs, regulate the amount of DC current supplied to the rotor. By adjusting the firing angle of the thyristors or the pulse width modulation (PWM) of the IGBTs, the excitation current can be precisely controlled.

Application to Rotor:

- The regulated DC current is supplied to the rotor field winding, creating a magnetic field. This magnetic field interacts with the stator’s rotating magnetic field, enabling synchronous operation.

Protection and Monitoring:

- The system includes protective relays and monitoring devices to safeguard against abnormal conditions, such as overcurrent or overvoltage. These protective measures ensure the safe and reliable operation of the synchronous machine.

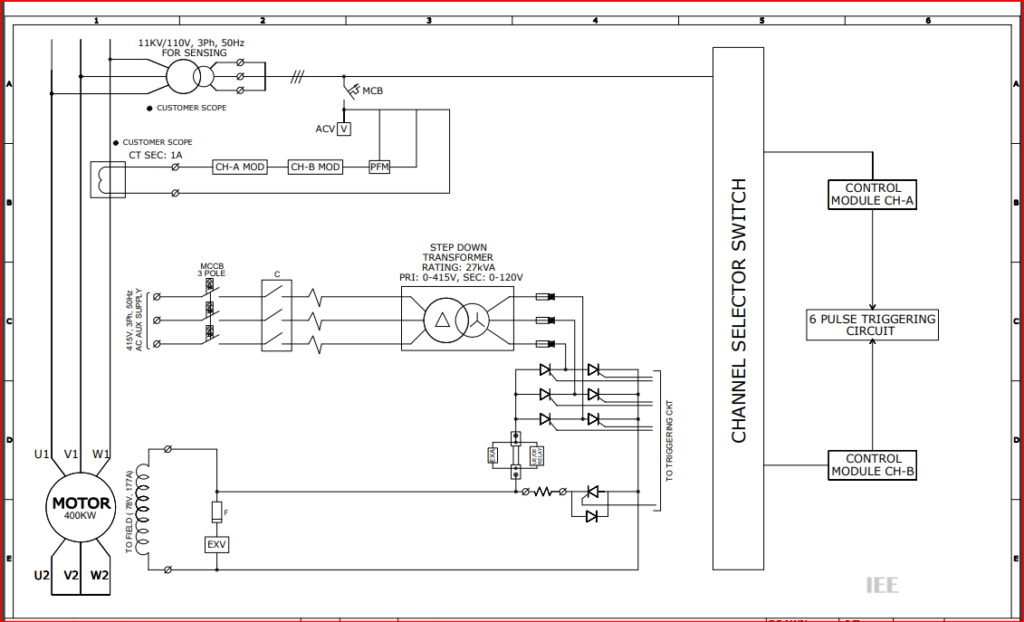

Circuit diagram of a Static excitation Panel

Advantages of Static Excitation Systems

- Improved Reliability:

The absence of moving parts reduces wear and tear, leading to higher reliability and lower maintenance requirements.

- Precision Control:

Static excitation systems offer precise control over the excitation current, resulting in stable voltage regulation and improved machine performance.

- Efficiency:

Enhanced efficiency due to reduced energy losses and optimized excitation current.

- Fast Response:

Rapid response to changes in load conditions, maintaining consistent performance and stability.

- Compact Design:

Static systems are typically more compact than traditional rotating exciters, saving space and reducing installation costs.

Conclusion

Static excitation systems are integral to the modern operation of synchronous machines, offering precise control, improved reliability, and enhanced efficiency. By employing advanced power electronic devices and sophisticated control mechanisms, these systems ensure optimal performance in a wide range of applications, from power generation and industrial drives to renewable energy and marine propulsion. Understanding the principles and benefits of static excitation systems is essential for leveraging their full potential in enhancing the performance and stability of synchronous machines.

Pingback: Strategic Sale and Market Impact : L&T sold its E&A business to Schneider Electric for ₹14,000 crore. -

Pingback: Overcurrent Relay Settings and Coordination (ANSI code 50/51) -